Archive

Thermal Integrity Profiling

In a recent email conversation with John Moran, he asked me how we at the NLE were quality assuring the large diameter bored piles (2.4m diameter). Good question I said, see my next blog. Actually it applies to both the diaphragm walls as well as the rotary bored piles.

The walls of the Battersea Station boxes are constructed with diaphragm walls. For those who don’t know (because I didn’t really until I got here) how they are constructed here’s a brief explanation.

Diaphragm Wall Construction

The piling rig looks similar to a rotary rig except that it has a massive set of jaws, instead of a rotary auger. I believe a diaphragm wall works like a secant pile wall though I am open to being told that I am wrong on this one.

The rig can cut a panel 1.2m deep, 2.6m wide (or wider) and almost as deep as you want. Each panel is dug under a bentonite slurry to support the excavation during the dig. A deep dig can take up to 7 days to excavate. Once excavated a reinforcement cage is dropped in and it is then concreted using a tremmie pipe.

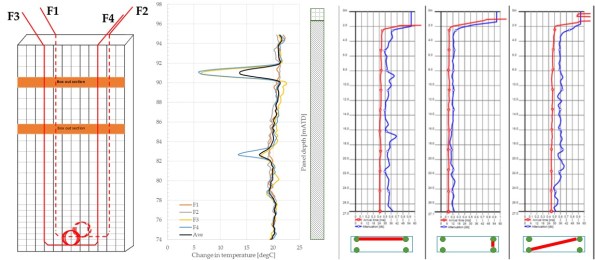

In TIP, a fibre optic cable is tied to the side of the cage. The technology uses a laser to shine a light through the fibre. Temperature is recorded by measuring the scatter backlight down the fibre at 1cm intervals. The system is accurate to 0.5°C.

The Bottom Cage showing the Fibre Optic Cable already laid out and two reels ready to extend to next cage.

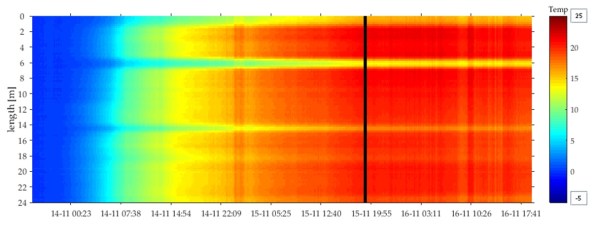

The instrumentation starts logging as soon as it goes in the ground and records for 48 hours after that. The output looks like the temperature diagram below.

Thermal Profile Over Time

The cold spots around 6 and 14m depth correspond to the boxed out sections where we have rows of couplers that will eventually connect to our floor slabs. The box out in effect shields the concrete from the surrounding soil changing the thermal profile. This also allow us to confirm that the couplers are at the right height.

For comparison, the first three panels were tested with sonic testing and TIP as a comparison. Since it was accepted as a valid method of assurance only TIP testing has been carried out on each panel. As the graphs below on the right show, sonic testing can only verify between the tubes and not outside.

TIP vs Sonic Testing (L-R Lay out of fibre optic cables, TIP testing, Sonic Testing)

In short, this seems like it will be the future of assuring the construction in deep large piles. The advantages of easier installation, testing coverage area and time of recording make it worth the initial cost of the system.

I know that Expanded (Laing O’Rourke piling specialist) use thermo-couplers but I believe that they only record every 30cm and can be quite temperamental.

CFS-N205-2360000-CIV-RPT-00028_Iss1