Prestress Losses and Excel

Apologies, but this blog is aimed at the Civils as a recap of Phase 1. My design team are now well into the detailed design stage of the three bridge widening packages I am working on.

One of the areas I have been focused on has been to check the prestressed Super-T Girders (pre-tensioned) that are being used on each bridge structure at the point of prestress transfer. So I thought I’d recap anyone interested in prestress losses for post tensioned members and thought I’d share the spreadsheet I’ve been working on for the last couple of weeks.

The Super-T’s are ‘off the shelf’ sections that have seen popular use across the state of Victoria for the last couple of decades. However, the lengths of these vary and as such, the choice of Super-T profile will be dependent on this, amongst other factors – generally the longer the span, the greater the moments etc.

My main role has been to check the concrete strengths (compressive and tensile) at the point of transfer. The precast Super-T’s are to be ‘steam’ cured to allow the prestress transfer to the concrete to occur at 24 hours.

Considering there are 3 bridge structures with a total of 12 spans ranging from 24m to 39m and proposed Super-T depths of 1200mm and 1500mm, I decided to create a spreadsheet to speed up the process – I initially started by hand, which was taking a long time and was very environmentally unfriendly!

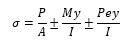

I started by going back to lecture notes/slides from Phase 1 and familiarised myself with Bungey, Mosley and Hulse (Reinforced Concrete Design to EC2); noting I am working to Australian Standards (AS5100.2 and AS5100.5 – so this could be of use to Mark) however it was useful for the analysis, such stress calculations:

For a pre-tensioned member such as this, prestress losses include: Elastic shortening of the concrete, creep and shrinkage of the concrete and relaxation of the steel.

The losses I was concerned with initially was the immediate losses at transfer. For pre-tensioned concrete, when the tendons are cut, and the prestress force is transferred to the member, the concrete undergoes immediate shortening due to prestress. The tendon also shortens by the same amount, which leads to loss in prestress.

Elastic shortening is dependent on the modular ratio and average stress in the concrete at the level of the tendons. Given there are 40+ strands at various distances above and below the centroid of the member (see section), I have taken a simplified approach, which is to use the centroid of the strands; this changes along the beam where some strands are de-bonded towards the end of the beam.

In short, the elastic shortening is quantified by the drop in prestress in a tendon due to the strain in the tendon. By calculating the strain in the tendon, it is possible to know the strain in the concrete as they are assumed the same; i.e. the concrete strain is the same as the steel strain. By knowing the strain in the concrete and the elastic modulus (which is taken at 24 hours), we can calculate the stress in the concrete – this is also true for the top and bottom of the beam.

Once the stress in the concrete at the top and bottom of the beam is known, we can check that compressive and tensile stresses are not exceeded at a concrete age of 24 hours. And by knowing the stress in the concrete at the centroid of the tendons, we can calculate the prestress loss. However, this is an iterative process, as the prestress originally used in the calculation (i.e. 100% of the jacking force) was incorrect as there was a loss – this is where excel makes it much quicker!!! (I have used the goal seeking function to do this).

In addition to this, I have included longer term effects by calculating creep and shrinkage losses, thermal effects (which includes a very funky polynomial graph to the 5th power – this took a day in itself to set up), and residual creep losses.

Anyway, I thought I’d share the spreadsheet (that is set up for the 1200mm deep Super-T’s in these pictures) for anyone interested or in case anyone finds themselves needing it – noting this is set up to Australian Standards and not EC.

The spreadsheet explains the critical points of the beam to check – as a note, I have set the critical points for one half of the beam only as beams are symmetrical. If anyone has any questions, feel free to ask!

I had trouble uploading the spreadsheet so there are some pictures below of the input data and summary pages or you can access via the following dropbox link: https://www.dropbox.com/s/uh68yephxky4rk3/Super%20T%20Prestress%20Losses%2C%20Thermal%20Effects%2C%20Creep%20and%20Shrinkage.xlsm?dl=0

On another note, my excel skills have improved drastically – turns out it is far more powerful than just creating nominal roles …

Apologies, I have just read this back and realised a mistake in para 10.

We calculate the strain in the concrete at the centroid of the tendon, which informs the strain in the steel (because they are assumed the same). By applying the modulus of elasticity of the tendons to the strain (Strain x E), we get the stress in the tendons. By multiplying this stress by the area of the tendons, we can calculate the prestress force and from there, decipher the percentage of prestress force loss (again, this requires iteration for the reason stated).

🙂 I enjoyed reading it! The challenge is that all of the lossess are interdependant. Creep occurs at a rate that depends upon stress, which changes elastic lossess etc. Eurocode makes allowance for this but ultimatley the important thing is to remember we are enigneering and so only have to know that we are the right side of safe not exactly where we are.

Thanks Richard. I’ve enjoyed getting into the prestress stuff and I’ll bear that in mind! Not sure if my sheet could be of use to Phase 1 guys or anyone heading out to Australia. But happy to send it over.

I started off with hand calcs, but given the number of girders we have, I caved in and turned to excel. The spreadsheet took me a considerable amount of time to create, as did going through the AS5100 bridge design series! I’ve used the spreadsheet a fair amount now, which has saved me a lot of time and even used my calcs on thermal losses/creep & Shrinkage to pick up mistakes on MIDAS CIVIL models used by some of the junior engineers.