Archive

Engineer..?

Period Covered 23 April – 4 May 12

Summary: Engineer…?

My responsibilities have grown considerably over the last 2 weeks as my role has shifted away from supervising to being a project engineer. This has happened rapidly and I have to balance my on site work with office based work. Efficient time management and communication has been essential as I have also been away from site for 4 days (AER writing, ANZAC Day and 2 days on a Safety Course.)

Also during this period the weather has shifted and the rains have begun. This has caused considerable disruption and as foreseen in my last blog it will be the simple/stupid errors that threaten the job and not the complicated technical aspects.

During this period I have completed the following:

- Supervision of GMF ground work contractors – bulk & detailed excavation and pile cropping

- Technical Anaylsis and plan for project dewatering, including brief to client. (Support from John M really appreciated)

- Dewatering Tender Analysis and award of $700,000 of dewatering work. (13 deep excavations and 180 pile caps)

- Dewatering Activity Method Statement written

- Given responsibility for approx. $3 million of Post Tensioning work. I will be responsible from writing the scope and schedule of work through the whole of the tender process to implementation on site.

- Completed TRA and Hazard Inspection audit

- Attended 2 day Safety Risk Leadership Course

- Safety Supervision

- Programme co-ordination meetings

Work on site. Exciting times on site as the Northern end of the service tunnel has begun to look like a tunnel with the blockwork wall being constructed and the formwork for the roof slab in place ready for a pour this week. Work on the remaining sections of the tunnel continues but the arrival of the rain has caused disruption (lost time, unable to waterproof in the wet and the problems with Syphon A, see below).

The remainder of the site continues its steady progression with the site opening up as the bulk excavations continue and piling the final portions of the retaining system has begun.

Finally, worthy of note is that work to divert a high pressure gas main in the North East Corner of site is due to occur on Monday. Once complete this will enable the completion of the logistics sliplane and provide a drive in/drive out solution to material deliveries. This work has been delayed for 3 months whilst the Client and Power company come to an agreement!!

Issues/observations. Water Water Everywhere:

With torrential rain arriving in Perth it has caused considerable problems for the Southern End of the Service tunnel.

The first bout of rain arrived overnight last Saturday and resulted in the collapse of an excavation. This was dramatic enough but was made worse as it covered the final portion of the service tunnel that had not had its slab poured. The collapse caused a 10m x 10m area containing the already the set out reinforcement ready for a pour on the Monday to be covered in sand. This took 3 days to clear as the reinforcement was stripped back and various “honeysuckers” were employed to clear the sand away from the mesh.

This meant by Thursday parity was reached. Just in time for another morning of torrential rain on Friday. What was first suspected as just bad luck (no one was on site to see the first collapse), turned out to actually be a simple mistake by the project.

In order to connect the hospital to the storm water system (run South to North) a serious of symphonic drains (connected chambers) are required to store water and divert it under the major energy services will run ( they run East to West). The syphons had not been fully constructed (not an issue in the dry) and the project had forgotten/not thought about capping the inflow from the rest of the surrounding area’s stormwater system.

As a result a “water flume” began pouring out of the unconnected syphon and flooding Area A again!!! After much wading around and “playing” with small grindex type pumps we lost the battle! A more permanent solution has been devised we plan to construct a sump where the stormwater enter site and a gilkes pump to pump water from the sump past the offending unbuilt symphonic drainage system and into the existing stormwater system.

Storyboard to Show Area A Problem

Further Work

- Continue with dewatering plan. Liaison with contractor, co-ordination with contract administrators and sub contractor to ensure delivery on site.

- Post tensioning work. Write tender plan and schedules in order to brief management on Wednesday and begin the tender bid process.

- Prepare for CI’s Visit.

JSP 101

Does anyone have the Word template for JSP 101 that I can install? I’m sick of trying to wrestle with Bill Gates about this paragraph alignment!

Is there a link I can download it from?

McFry

PS – The motor Vehicle Authority boils my piss!

This will get me beaten up for sure….

My pals at USACE do not find this funny….at all.

We said “NO BLASTING!”…we just don’t know why…

General

Have been offered the chance to do a 1-week project management course (PMP in the title)….and have politely declined.

Am now in the systems for DR Checks, PROJNET and RMS…….now I have to figure out what all that means. Am conducting some online training for which USACE makes excellent use of youtube! Very professional too.

EDC Solar Wall

Have rejected Contractor’s requests to design based on assumption (it’s the sort of thing I do on projects for John and his black magic soil mechanics – so you can’t shit a shitter). Have insisted on a survey and at every step they seem to upset the Client by making assumtions that they can just turn up and dismantle a mission critical distribution centre at will. Have coordinated accordingly and spoken several times ‘off line’ to help keep the parish at peace. I detected initial resistance to stumping up the costs for the investigation but a phone call to the CEO about bidding on a multi-million dollar project and then offering the most minimal of investigations after award has resolved the issue….especially seeing as there are more projects up for grabs.

Have refused requests for submittals to be delivered on a bi-weekly basis for review. This is based on issues observed on the Ashley project where this happened early on and caused delays that became contentios as to who caused them. Technically they were overdue from USACE, but technically the Contractor sat on them too and when the bulk arrived there was no prioritisation…. Just pay for the extra stamps and have done with it.

Have learned that I will be involved in two more solar wall projects that are currently at design stage.

HQ Project

The USACE geo geeks have tried to tackle the issue of blasting with the Client by delivering a presentation on how safe it is. I added my own experience on how far we can make steel girders fly when using ‘P for plenty’. The key pointr we found was that everyone from th eClient’s team knows that there is no blasting under any circumstances….they just don’t know why…or even if it’s written down anywhere. My thoughts are that it will be approved.

Other items that came to light are that a sewer running through the proposed site is to be replaced as part of the project (but only under the footprint of the building). The Client has admitted that it is currently in a state of disrepair, damaged and leaking. Then they wanted to know what assurances they have that blasting will not worsen the sewer and how they prove or disprove that the Contractor will or will not be liable. He then joked that either way he would prove it to be their fault. My comments were that actually USACE would have to act to protect the contractor in those circumstances. They then mentioned that they have aspirations to repair the sewer. I will tactfully pry and enquire as to why they aren’t pushing to do some joined up engineering and schedule the repairs to coincide with the HQ project, reducing risk, potentially lowering costs and providing better value.

Ashley Reservist Centre

The issue of the concrete pours and quality assurance / control are becoming critical. Have been authorised to travel to site and book overnight stays if necessary to get amongst the problem and find the best way to proceed. This is going to be a case of balencing the effect on delays and cost with the residual risk retained by the Corps. Simple solution = tear it all out and start again = delays + Costs + contractor potentially making a huge loss and going bust = more delay + re-letting etc etc. Alternative solution = allow more testing and verification + fix the QC / QA problems + minimise re-builds + minimise delays = potential for future failures of the concrete to be on the USACE flick. How ill the intrepid hero fair? Will they find a solution? Who invented liquid soap? Tune in next time for the continuing adventures of Herge’s Tin Tin and the Reservist Centre of Contractual Doom.

In Other News

Botox for kids advertised on TV…….only in America.

Have added rackoon, porcupine, turkey vulture, hare and possibly an aardvark (only 30% sure on that one) to the road kill identification register. Rackoon seems most durable to date.

Mr Country Man continues to have life kick the crap out of him. Mentioned this to the lady in the garage who suggested that playing it backwards has an amazing effect. His wife comes back, the dog is resurrected, he wins the lottery and lives happily ever after.

Have great day y’all.

McFry

Now I’m not an E&M, but…..

That looks fine to me. Approved!

Week 6 – 16-21 April 12 – Just ticking over

This week has been quiet as the Project Leader, Barry, has taken 2 weeks annual leave back on the Emerald Isle which means that all is quiet on the Jetty front. Barry has left me in charge by virtue of my seniority and ability to get things done but there is not that much happening. On the Friday of the previous week we had received a letter from Bechtel stating that the project start date would be in the window of July to October. This means that we have no certainty, no ability to commit to contracts as we don’t know when they’ll start and I have that nagging feeling that if it continues on I may be at risk of failing to complete my DOs. That said, things may start in July and potentially the enabling works could begin before that, which is actually one of my subcontracts. Once the birth has happened and my paternity leave over I’ll need to fully assess what is happening with this project and whether my DOs are achievable. I suspect that this might best be discussed during the CI’s visit in late May.

The week has been spent finalising Activity Method Statements to find out that the risk assessment format has just been changed by JHG and need to be rewritten. Joy! So at least that’s something for next week. Also, I have been working on some pile testing stuff in conjunction with the Brisbane design office. Finally has been trying to get involved in meetings and discussions that Barry would normally be in to find that people are only interested in the organ grinder and not the monkey! This week I have allowed it to happen but next week I will be a little firmer with them and make sure that they include me in their discussions.

One good thing that did happen was that I organised a trip on Friday to the JHG workshops in Rockhampton, an hour and a half north of Gladstone. We went and saw the pile gates for one of our piling barges and inspected their workshops as one of our suppliers. A good trip, similar to the Civils trip to NuSteel, only with slightly less to see and nowhere near as tidy around the edges. Some big positives though in that neither of the junior engineers had been to/seen a workshop like this so a good development opportunity for each of them.

Not a great deal else to report without a site to actually be working on! (Note the frustration in the writers tone tempered with the fact that his wife is about to give birth and being quiet on site is not such a bad thing when about to take 2 weeks paternity leave!)

It has been a sad week personally with the loss of not one but 2 dogs. Jackson was put to sleep and then on Saturday I got a call saying that Blaze had started whelping! Unknown to us, Blaze had been knocked up by the foster carer’s dog, which was supposedly neutered! Blaze is 7 (70 in human years) and in no state for this and so she went to the vet for a c-section. After Blaze had got out of the car a still-born pup was found wrapped in blankets. The vet x-rayed her and could not see any more pups which is not surprising with her age. So an overall sad week for Blaze and my parents who have stepped in and had to deal with all of this trauma. It’s also been fairly hard on Team Serevena with mini-me the third due any day now as we enter week 40 of the pregnancy.

Looking ahead, next week will be fairly quiet again giving me the opportunity to finalise AER 2 and my thesis proposal. It’s also a bit stop start with Wednesday off for Anzac Day on Wed. I have been invited to the dawn service and shall be attending to pay my respects. Beyond that, it’s building up for another R&R break the following week so most people will be winding down from now on.

Week 3. 16th – 20th April 2012

Ask and you shall be given

Just as it seemed there would be little work to do, I am now working for 3 different programme managers on three completely unrelated tasks – in fact I’m wondering if one of them has any relevance for me at all… In addition to the Bruce P60 Bridge Bearing Access Platforms (I’ve written the SOR which is now being reviewed by the Programme Manager) I am working on the following:

Study into the Eastern Trough Area Project (ETAP) platform POB (Persons on Board). Prior to putting more accommodation modules (or similar) on the ETAP platform I have been tasked with working out what the addition of manpower would mean – more lifeboats (certainly); more kitchen space (probably); increased electrical demand, HVAC, water and everything else (you betcha), another helipad (maybe not). Presently ETAP can hold 113 POB, so 30 more is a fair increase. I also need to delve around and see if the figure of 30 is an ‘all-in’ figure inclusive of logistics (cooking, cleaning etc) or if that is for drilling alone, and so more support staff would be needed. And work out who said 30 in the first instance anyway!!! Having not been onto ETAP or any other platform yet I’m still not completely au fait with the goings on off-shore, so a recce is definitely required!

Depending on the results of this self-defined study, I might find myself designing new accommodation to go on the platform or doing a cost-analysis of different options – accommodation barges for peak periods, daily commutes or use of floatels. Although this analysis is not engineering per se, this task (which could end up pretty huge – we’re talking about spending many £ms here) will require me to get involved with many different departments in the SPU (Strategic Performance Unit – I am in the North Sea SPU) and test my critical analysis. It will almost certainly get me off-shore too which will be good.

ETAP Platform at night

Runcorn – is it working? Nine months ago our main design-house contractor, PSN, were asked by BP to expand their engineering capacity. They did this by forming an office in Runcorn, Cheshire, who now deal with some of our design tasks and other engineering. But – as I found out first-hand at our team meeting a fortnight ago, the BP staff are rather dubious about its effectiveness. Here, the PSN guys here can easily be called in for meetings, or chatted to informally, but there is a thought that Runcorn is taking a bit longer, and so steps in Captain Warner to investigate. This is clearly not engineering, but very much focussed on management of contracts and HR. Will it be useful for me? I think it will give me a better idea of how things work/ don’t work and certainly it will build my business acumen as I delve into hours worked and Cost Value Reporting (CVR) by different offices. Some indications actually suggest that the engineering done there is better than here and that the only problem lies in the cost reporting: maybe all that is required is a restructure and better use of conference calls or Skype – most of us have webcams on our work laptops, after all!

Other bits – work

Courses completed this week include on-line and face-to-face Management of Change training, something that BP are very big on, having put a failure of Change Management down as a key factor in both the Flixborough and Grangemouth disasters. I can now start the procedure of affecting any process, plant or people changes on the system.

This week I also got to wear my PPE, as I watched a rehearsal for a crane lift of a piece of duct. Yes, really. This is one of Ish’s jobs that will get handed my way: taking off the old Low Pressure Booster Comressor (LPBC) stack off Magnus and replacing it with a new one. Every lift of anything <25kg is a big deal offshore, and as I understand it must be done using a crane or similar. People get very worried that if anything falls off the platform it may come to rest abruptly on some pipeline a hundred metres below, and we don’t want that!

Next week I am away on course all week, completing the 2-day Minimum Industry Safety Training (MIST) and 3-day Basic Offshore Safety Induction and Emergency Training (BOSIET) courses, which will finally allow me to go off-shore.

Other bits – not work

The cycle to work (70-mile round trip) is not pleasant with a headwind in the rain.

Running in the Cairngorms is awesome, no matter what the weather (last weekend). Scrambling in the Cairngorms is still ‘winter conditions’ as today proved, and outstanding.

And I’m getting to meet some of the local community: in my role of the incoming Adjutant, Capt Warner’s husband, I went for (Queen’s birthday) drinks yesterday at the Lord Lieutenant of Moray’s house and tipped my hat to the local MP, a retired General and various local dignitaries.

Geo questions for HQ – Solar Wall RFI’s – Concrete issues on reservist centre – Country and Western Radio sucks.

Took some leave while the kids were here and took the opportunity to visit Washington DC and Baltimore to see the museums and monuments etc. Apparently we’re still just as embarrassing to the kids as ever. Lukas is now home safe and we pack Adi off tomorrow so that naked house can resume.

HQ PROJECT

The design has been out with the contractors for a while and bids have been received. They are to be assessed on value engineering criteria as well as price but there has been a large number of RFI’s submitted that need to be answered. The majority are to do with geotechnical issues and uncertainties with the piling requirements. We have a group called Geotech within USACE who did the original design and a lot of the cross-issues that related to contractual issues have been ironed out. The next step will be to consolidate the RFI’s and distribute and release ammendments to specifications and drawings to ensure that the contractors have an opportunity to revise their submissions before the final award is released.

Key issue at the minute is that the original specification stated ‘no blasting’ for the foundations etc but on a subsequent issue the wrong document specification was adjusted and released. This had 5 pages of specs on how blasting will take place. The facility big wigs are not willing to allow blasting to take place as we are near to a live airfield and family housing and the use of the work ‘explosives’ seem to make them jumpy. We have arranged a meeting for next monday to try and convince them that we can actually blast without knocking aeroplanes out of the sky or killing small children. The main reason for this is that the project is likely to suffer to the tune of $2M if we now deny the contractors this method of removing rock.

ASHLEY RESERVIST CENTRE

More developments with insufficient quality control with concrete pours on behalf of the contractor. USACE now needs to work out if they make the contractor rip out existing sections and re-pour and how the contractor can begin to rectify their actions. Am considering offering my services to look back though the records and come up with proposals for how we proceed with minimal impact to the project. (request advice from PEW staff as to whether this is a browny point scoring opportunity for review.)

There are also issues with the proposed method of nailing ceiling boards to corrugated steel sheets…..apparently nails don’t go through corrugated steel too well. I immediately started to try and come up with various suggestions on how we could overcome this, but this is a big no no. USACE avoids at all cost telling the contractor how he should do something because if this subsequently turns out to be a problem, they have no comeback, whereas if the contractor submits a proposal and USACE agrees to HIS proposal, the contractor still carries the risk. I am now potentially in a bizarre situation where I can suggest ideas to the contractor, who would then have to suggest them back to me, so that I might approve them……I’m sure there’s a catch somewhere in there!

SOLARWALL PROJECT

I have also been getting my head around the Solar Wall project on building 2001 here on the base. We had some RFI’s for structural as built drawings for the racking systems inside the warehouse (as they support the roof) and also for wall construction details so that the structural engineers can demonstrate that the existing walls can support the solarwall product. This was initially passed to the Client (Defence Logistics Agency) as they actually hold all drawings pertaining to the facility. The structural engineers are not content that they have sufficient information from the older sections of the building and want to work from ‘assumptions’. The Client is not willing to spend more time looking through their historical records (as they have spent many hours already and are busy). The structural engineers are unwilling to send someone in person to look for additional drawings as they are in Texas and the Client is now understandably peeved.

I have been discussing other hierarchy issues and have been trying to understand where various responsibilities lie and where different bucks stop. In the end I still get the ‘shared responsibility’ line and have decided that I will push all matters but in consultation with the others before addressing the contractors direct. Ultimately I wouldn’t be willing to allow the design to be ‘proven’ with such vague assumptions and will insist on some additional action on behalf of the structural engineer (SE). In the spirit of mutual cooperation I will arrange for myself and another project engineer to try and tackle the drawings issue provided the SE sends a local representative to assist. I will also investigate the feasibility of removing existing wall sections to see how they were built. If this turns out to be a 10 man and a crane type of job then it’s probably too much effort. If it’s 2 men and a screwdriver then the SE can get his rep down here pronto….especially seeing as the total value of this is $3.8M and it would be unwise to allow him to carry such risk. I have held a separate meeting with the client to get him to confirm that he will be willing to assist in any reasonable way with the removal of existing wall panels. This meeting also revealed that the Client has undertaken a similar project previously but without the assistance of USACE as the dollar value was below the threshold. This means we now must extract as much history and lessons learned as possible. If this were a civilian client this would not be a problem because it’s in their best interests from a financial point of view, but for a government agency as a Client, this is less of a concern because the money is not theirs and for them it is good to be able to offload the responsibility to a third party.

Other developments include refining of the submission requirements and that some initial submittal requirements can be deleted all together. These are things such as environmental assessments and historical building impacts. The whole project is aimed at improving energy efficiency and by definition it is a inappropriate to try and justify or score points in a discrete manner. The whole thing is a big tick in the box so no further work is required. Historically the building is deemed by the client to have no significance and therefore no heritage is affected. My next step will be to press the contractor for a revised schedule and to highlight key areas that need lead times and also to tie in the schedule with his submittal requirements.

IN CAR COMMUTING ACTIVITIES

Tried to see if the telephone messaging option for blogging would allow me to save time and make better use of the daily commute….it is not recommended. I will stick to e-mail to update blogging.

My dead animal road kill observational skills are improving. I can now readily identify rabbits, foxes, skunks and possums. I am unsure about a particularly chubby looking thing that might be a Marmot of some sort. Will have to wait until another one dies as they don’t age well in the highway.

Mr Country and Western singer man is starting to get to me now. Today he sang about how he can leave his door unlocked and how cool it is to drive a pickup truck (and actually have a use for it – unlike the city folk). Yesterday he was unhappy because because his wife left him (assuming it’s his wife – he referred to her as ‘my girl’) but at least his faithful dog is still with him. A while back he was actually happy because he got some sort of new tractor but I assume ‘his girl’ has left with the tractor as he was particularly miserable about the whole affair. I normally get through about half a song before I have to turn it off – I am afraid I may build up a tolerance to country music….and that’s not cool.

AND IN OTHER NEWS

I am now the proud owner of a Maryland driver’s licence having gone through the indignity of having to take my test again. It took all I had to mask the bad habits picked up over the years. The worst bit was trying to pretend I knew where the wind-screen wiper controls were in the wife’s car when it started raining during the test. The examiner probably wondered why I kept switching the over-drive on and off, but hey, it’s not a fail criteria. The whole thing did almost came to an unceremonious end when prior to the test I presented the clerk with my 3-hour drug and alcohol awareness certificate (framed) and she realised the contempt I hold for the whole system. She’s clearly very proud of their bureaucracy.

Until next time.

McFry

Project Great – Scuba Awesome – House a Bit Tasty

Well hello everybody – I’ve finally found some internet! Hope you are all having a good time. Well done us all on APMP – I wonder how that bloke did – you know the one. Also, we all got 61% for our final design exercise.

The work bit first…

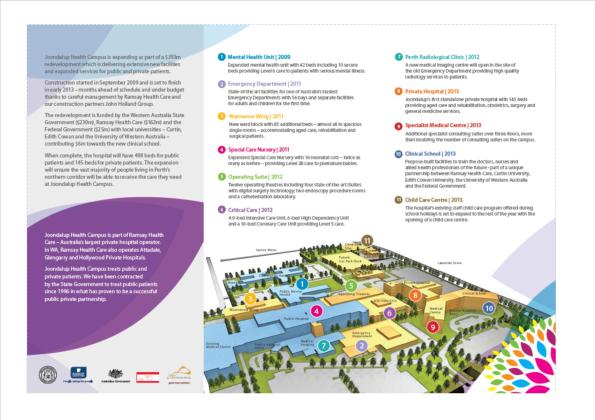

My phase 2 attachment is at the redevelopment of the Joondalup Medical Campus, which comprises the refurbishment and extension of an existing hospital and the construction of a second, private, hospital and teaching facility, including the modernisation of all services. On site interdependent projects have been let to and formed by John Holland Group, into a programme of projects – The APM would be proud. The procurement strategy selected by the client, Ramsey Health Care, is a combination of a management contract and construction management (some sub-contracts are directly let by the client), with the addition of a target price agreement. The details of the head contract are a little opaque; the Programme Manager is keen on keeping the financial stuff to himself. In any event the project is, at least overall, ahead of schedule and showing a healthy gain share for all concerned.

My role, initially, is to be the Services Coordinator for the project that will deliver the refurbishment of the existing hospital.

The nomenclature used by the Organisation differs from the standard APM model, in that the post that the APM would call the Programme Manager is referred to as Project Manager, whilst the posts that the APM would label the Project Managers are known as the Site Managers.

Attached is a briefing slide giving an overview of the programme; my project/role is concerned with elements 4, 5, 6, and 7. Because these elements are to be delivered during the period of my attachment, I will have exposure to procurement, demolition, installation and commissioning of a wide range of services.

Specifically, I’ve been given responsibility for a smaller project within element 5 – the refurbishment of a day procedures surgical unit, to be delivered by the end of August – all very exciting but I’m having to learn pretty rapido. Mostly, I’m reviewing tender submissions in the office, whilst acting as a middle man between the clients design consultants (from whom I have to get permission for almost every change), the clinicians (who want it finished yesterday but won’t let me turn the water off for half an hour) and the sub-contractors (Who ‘just wan’a smash it in mate; what’s the blady howld ap?’) on site. The work is being let piecemeal so there is much frustration, for the sub-contractors as well as for us, in getting the approvals required to put hammer to wall.

The hospital is still running as we build, and taking over the new facilities as they are completed. This poses some unusual challenges – I had to scrub in the other day so I could poke about in a live theatre looking for an elusive set of medical gas isolation valves. The mantra is very much hospital first, building site second. My little project is linked by a door (now chained shut) to a post op recovery suite. One of the others is in the space between the theatres and the recovery suite – the bricks and sticks men are being very good at not swearing to loudly.

The hospital is still running as we build, and taking over the new facilities as they are completed. This poses some unusual challenges – I had to scrub in the other day so I could poke about in a live theatre looking for an elusive set of medical gas isolation valves. The mantra is very much hospital first, building site second. My little project is linked by a door (now chained shut) to a post op recovery suite. One of the others is in the space between the theatres and the recovery suite – the bricks and sticks men are being very good at not swearing to loudly.

Mark was right to tell us that we would have a technical edge on most of the others on site – much use of Darcy’s equation to explain why ‘that duct isn’t going to be big enough’. I’ve not had to invoke rule number 1 yet, but rule number 2 is becoming my go to option, since one of the things I have to do is review the detailed technical designs produced by the sub-contractors, and then persuade the client’s consultants to give us authority to proceed. In some ways there is tremendous freedom to make engineering decisions but on the other hand much is tediously bureaucratic.

Away from work, there is much wailing and gnashing of teeth with finding somewhere to live. The place they have put me in is frankly…, well it’s not nice. Burnt out cars, no hot water, red back spiders, and a curiously persistent shopping trolley in the last few days alone. I will be moving soon!

Mine are a little bigger than this one :-).

On the other hand, I managed to do some awesome scuba over the Easter WE; I came face to face (well almost… ok, it was about 20m away) with a juvenile (2m) Tiger Shark. Was very cool in any event.

That’s all for now folks. See you here again soon.

APMP…

Kenny found my results in the Mess pigeion hole, seems I got a high of 100% for question nine, low of 48% for question four and an average of 63%. Seems that leaving the KGV at midnight (following Geek Club) paid off. How did everyone else do?