Archive

Dewatering Dramas – 22 May – 14 Jun

Period Covered 22 May – 14 Jun 12

Summary: Dewaterng

A really busy few weeks, ensuring that the Dewatering Package was given State Approval, the contract was signed between JHG and the Subcontractor (Mobile Dewatering) and making sure all of the necessary prep work and safety paperwork was in place for their arrival.

To be brutally honest I have learnt an awful lot and though John Holland are happy with everything I would do things differently if I had my time again….I have learnt valuable lessons about risk V programme but am pleased to report as I write this with things are getting back on track, abeilt with a significant delay.

Key lesson learnt – Water has the potential to be very dangerous…..

During this period I have completed the following on top of routine work:

- Consultations with client to convince them original dewatering plan is most sensible and to discount sewer option.

- Written Groundwater Management Plan

- Dewatering Activity Method Statement written. The mountain of other H&S paperwork (Plan Hazard Assessments, Task Risk Assessments, Induction paperwork)

- Chaired subcontractor kickoff meeting

- Dewatering Co-ordination and installation (including installation of 1 x Monitoring Pizo)

- Re-infiltration licence approval from Department of Water

- Emergency storm repairs

- Dewatering QS work

- State approval reports written for bus stop relocation and Sunday working

Work on site.

Dewatering Set Up slide show…. from start to finish (Sorry its in 3 ppts)

So its all about me at the moment. Works has slowed to a crawl as the site waits for the dewatering to begin. The delay is a result of a combination of factors but the finger can be pointed to some slow work by the John Holland contract administrators and the client perusing an option that they had discounted 2 months earlier. All this meant the subcontractor did not start on site until 5 days after dewatering was due to start. With 10 days of set up and installation required this is a significant delay.

I will cover the whole saga and the different options to dispose of the water in my next AER, but in short the water table needs to be lowered by 0.5 -1m around 180 pile caps and up to 2.5m around the cores (10 in total). The water will be treated on site and reinfiltrated back in to the ground through 30 recharge spears.

Temporary work: Part 1

Due to the delay in mobilising to site, a temporary solution for disposing of the extracted water was proposed whilst the permanent system was being installed. A temporary reservoir/sump was dug. Unfortunately this was way too small and breached over the first night. Unfortunately the water did not flow in the direction of the open “floodplain” we had cleared but cut a deep channel at 90 degrees to the proposed overflow area. This resulted in 2 legs of an access scaffolding being undermined and another subcontractors compressor being tipped over. As a result Saturday morning was spent doing a lot of emergency works to rectify this issue. Thankfully no one hurt, but a reminder of the danger of trying to contain a large body of water.

Temporary Works Part 2.

Having learnt this lesson you would think we couldn’t possibly try this again, but the pressure on the work package manager to remain on programme is such that a second larger reservoir was constructed in another corner of site. Understanding the permeability of the soil better and the flow rate I calculated that this second reservoir was very likely to overflow after 16hours and it was not worth the risk involved (dewatering needed to last at least 4 days to bridge the gap to the permanent system). Overruled, the pumping began….as you can see in the photos this very nearly ended in disaster again, with the pump being turned of with just 10cm to spare at 630am the following day.

As a result of these 2 instances the decision was made to wait for the main reinfilatration system to be set up.

This began on 20 June and so far has worked very well. Currently a 110m2 area is being dewatered with the number of excavation steadily increasing over the next 2 weeks – due to the limitation of the treatment units the amount of water which can be dewatered at one time is 30l/s so careful manageme

nt and programmeing is required

In other news…has Chris W been let loose on the cranes in Perth (view from my site office looking out on the new cancer centre building). Strong winds in Perth, Western Australia, took the luffing jib of a tower crane over the back and onto the roof of a hospital on Sunday as winds as high as 140kph caused widespread damage to the region. While not yet fully confirmed we believe that the site was closed when the incident occurred and the crane was parked up with the jib at around 75 degrees and the slew brake left on, rather than the crane being allowed to ‘weathervane’.

Further Work

- Dewatering Programme Planning

- Environmental Monitoring

- Work on use of Stormwater System

- Post Tensioning Tender Review (awaiting for State to lift moratorium on all tenders…….long story!!)

- AER 3 – Dewatering, Health and Safety Paperwork and Boundary issues on Site, Relationship between Client, Existing hospital and JHG.

- TMR 2 Research – Project Bespoke Contract v NEC3/ICE 7th

A more focussed week…

Fewer topics but with more devils in the detail this week.

EDC SolarWall:

The contractor is busy working away on the 65% design solution buthas submitted a risk analysis (more a project management risk assessment than anything else) I offered suggestions on minimising risk to supply chains by having a floating stock and to help coordination between the facility and the work details by having primary and back up work plans. Discussion and costing of aesthetic options for the wall supports continues.

Ashley Reservist Centre

I am helping to identify a laboratory that can conduct the relevant testing for the core samples. It seems we’ve never had petrographic testing done before on any of these jobs. We have also liberated some core samples that came from the foundations a couple of weeks ago. From photographs that were sent in from site I pointed out (almost reluctantly) that the rebar was way too close to the surface – so now we may not even be able to trust the foundations it’s built on! This becomes more of a mess as time goes on. We liberated the cores so that they too can be tested. How this will be held against the contractor I do not know – the likelyhood is that it will simply be recorded in the logs for in the event of future defects arising. Personally I feel that if this was a civilian owned contract they would be in the thick of litigation by now, but the cost to the tax payer is already too high for what we are getting for this project.

C4 ISR Tobyhanna

This is a new one to play with. This is a completed structure that overran (suprise suprise) due to monumental mess ups with the design provided by USACE. The project was for a finishing centre for vehicles where they undergo re-fit and and spreayed etc. It went out to tender with an electrical design that didn’t even cover the requirements for the spray booths themselves and as such the whole thing was not fit for purpose. The re-design then changed the structural design and several revisions to the project were required. It appears the main contractor entered into several sub-contracts and now as a result of the iterative redisgn process, huge delays and changes he is hitting USACE for litigation / request for equitable adjustment in the region of $1.25M with more to come……

The letter itself is a 40 page document with an accompanying five inch thick file of exhibits. I have devised a tool for collaborating between the many disciplines that are going to have to pour through this and have conducted the first iteration of input. The intention is to pin as many issues at the lowest level before raising outstanding issues to the next level and formulating a coordinated response. I managed to catch the ear of the District Commander recently and he reckoned the whole thing wouldn’t be settled for less than $2M…so I reckon it’s not as bad as it could have been. I am now working through the various issues and conducting triage on the fall-out tasks. The country is 16 Trillion in debt and I understand why! I am trying to minimise this as much as possible but in a fair manner…. I will also be holding a bring and buy sale to help relieve the national debt. This will go on for some time.

And in other news:

After successfully conducting investigations in Spanish for the Harpersferry Project – I have now successfully used my English skills to order a pizza on the phone…it’s surprising how many folk can’t understand a word I say. [Yes Roy that’s no different to normal I know – it must be a Yorkshire thing].

Child number one is now back with us in the US. We now need to occupy him for 13 weeks (suggestions welcomed). He was seriously unimpressed when the first thing we did was take him to the social security office so we can apply for a work permit for him. We will soon have him in a sweat shop somewhere downtown.

For Sale – Cheap sweatshirts (coming soon)

Only 2 shootings nearby this weekend….and no face eating…which is a bonus.

First couple of weeks of June

Topics I have worked on

Controls systems – SSP user interface review, and RIID sensor location etc

In the past couple of weeks I have become much more involved with the control system on the two projects. Within the SSP this has involved reviewing the User Interface that has been produced by the controls subcontractor and comparing this with what is required and what is asked for in the specification. Of course all 3 of these are different, and so I had to try and come to a solution which will please the customer and not cost any more, (i.e. not vary far from the specification, and generally trade one step out to two steps back). It did bring it home quite how similar all control systems are; I could really see the value of the controls module we did, although I really wouldn’t want to write the ladder logic for this system. The crux of the situation is that the information is in the system, but the user interface is not displaying as required.

Within the RIID project I have been working with the contractor, subbies and Architects/Engineers to ensure the correct sensors are collecting the correct information from the correct locations. The shop drawings (which were previously accepted by the Corp, but also have the caveat that if we made a mistake it’s not our problem) vary from the design schematics at some points. The data that will be lost due to the differences has to be either classified as irrelevant anyway (something the designer is unwilling to do, in case they realise why it was important later on), or we need to extrapolate it out from other data or the suchlike.

In order to get the cycle of “construction > problem > question > answer” moving more quickly I convened a few different meetings with the various parties. I found that the Architects/Engineers, whilst being very intelligent and very quick on the uptake, find every question interesting and meriting further research, and so I had to keeping pushing hard to get back towards a triage mentality, as we had over 50 different issues to address. These worked well, as we managed to return 20 in 2 days, and assign 25 to further research, and pass the rest to more relevant POCs.

SSP – Squirty bottle inspection of sealant – keep it simple

Things are now very quiet in the smaller project of the SSP, as we are so close to completion, but also having to wait until the design variation has been approved and checked. We have occasional inspections, such as the inspection of the contractors-suggested-variation for sealing the pipe insulation ends, a good example of keeping things simple. The food coloured water was able to be wiped off – test pass!

CI’s Visit

As far as we are aware the CI’s visit went well. It has thrown up some interesting discussion for me and Matt to research, namely the possibility of doing some of the courses run by USACE for their engineers, as part of an induction to USACE process.

Of interest

Lines drawn in the sand, union interaction and quality of work.

There is some trouble continuing to rumble on site as the pipe fitters union is upset that the sheet metal workers are “encroaching” on their turf. This has happened due to the fact that the exhaust air from the high containment labs is piped rather than ducted, to give the highest level of containment possible. The sheet metal workers are responsible for all the air systems, and so have been fitting pipes where relevant. Clearly the pipe fitters union is upset that the work has not gone to them. At the moment the situation is stable, but it is an interesting study into the dynamics of unions. The quality of the work seems to be adequate in the most part.

Prices will always edge up – Corp holds onto small credit for negotiation, contractor places all costs in.

A couple of the problems that I have solved should have resulted in a small (few thousand dollars) credit, however due to the cost of chasing these credits no gain would be felt, so they are recorded for future haggling. When the contractor is given a variation they charge for everything they can, and as a result the cost of the project will always edge up, and of course the variations are excluded from the gain share pain share calculations.

And on the lighter side

Phosphorus in the sewage plant

We have been having problems recently with the local sewage plant accusing us of killing their “good bacteria” with too much phosphorus in the sewage. They have pointed the finger at our Fort Detrick by following the trail back to the camp gate, and then by deduction it was assumed to be the massive building site in the middle of camp. There was a lot of accusatory finger pointing as to who had been illegally dumping into the drains, until I pointed out that the storm water would likely have a lot of fertilizer in it. The Americans hadn’t thought of this as almost all of their systems keep storm water entirely separate from black water. On inspection there are some antiquated systems on camp that still have cross connections, so this seems to have explained the problem, and shifted the blame away from us. No idea how they are going to solve the phosphorus though… (Not my problem…)

Queens’s diamond jubilee party

Sarah and I hosted a Party to Celebrate the Queens Diamond Jubilee (which oddly enough isn’t a public holiday in America), and invited a good portion of the office round to our place. We had managed to buy-up pretty much every Union Jack Flag from across the states, and had them up everywhere in our house. I’m still not sure whether the guys though this was normal, or whether they were being polite by not laughing at the Red/White/Blue house. It went off well serving all the English traditions like cream teas, Pimms and slightly burnt BBQ.

My home brew

The first batch of home brew is almost ready… and I have already tried it: seems pretty good, but also quite heavy – not really a session beer (as I believe it is described).

Weeks 9 – 11. 28th May – 16th June 2012

Weeks 9 and 11.

It’s all “normal jogging” at the moment here in the Dyce office, with the following keeping me ticking over:

[Magnus] Glycol pressure relief system. Hugh (Programme Manager) and I worked through the Appraise and Select gates for this, and I’ve now kicked off the Define phase of the project with the WG PSN design house in Runcorn. Their piping, process and structural engineers will all work on the specified design piping design, whilst further contracting out the installation of Passive Fire Protection (PFP) to the glycol reboiler and heat exchangers. This new design must be executed during next year’s turnaround (TAR) window that starts 1 June 2013. During the TAR the whole platform is closed down, costing £m per day in lost revenue.

The pressure relief system is fairly simple in itself; a change from a 1” pipe to a 2” pipe. From the P&IDs (Piping and Instrument Diagrams) there is even a spare 2” nozzle to tap into, but looking at a photo (below) it’s not immediately clear where this is, and we may have to tap into the bridle instead. If I ever get offshore I may be able to have a look…

As the SPA for this, I ensure that WG PSN aren’t wasting time (£) producing nugatory work throughout the phase, and also grip them when things slow down. I report to Hugh and liaise with the TAR team – and do my bit to stop them from putting their noses in too much!

[Magnus] Installation of DBBs on the Condensate Pumps.

Just as the glycol pressure relief is required because it is currently ‘unsafe’ (if there was a fire, it’s calculated that the pressure increase in the boilers would be well above the design pressure and lead to catastrophic failure), the conde pumps are not SIRPS (Safe Isolation and Reinstatement of Plant) compliant, meaning that the pumps (the two conde pumps operate in parallel) cannot be taken off line without a complete train outage. So… some new valves need adding – simples! And it does seem pretty simple really! Because the installation will be conducted during the TAR, the trains will be fully bled and the new valves installed in place of the old ones. The new double block and bleed valves will allow for work to be done on the plant whilst the other part of the system remains leve

Is it really that easy? Of course not. The P&IDs show that the pipework is made of Incoloy 825, and so any new valves must be of the same material. Are these available off the shelf? Almost undoubtedly not, and so are a long lead item. One of my main deliverables at the kickoff meeting was to find the lead time for these – it might be that they are sourced and the pipework designed around them if the lead time is that long!

ETAP ALQ.

With the Appraise resting on a survey (recce), one may be mistaken that this would be a priority and a 6-week waiver given for my visit. But alas, the Offshore Installation Manager (OIM) hasn’t granted this. Cue a few terse e-mails from John (Programme Manager), and now we are just waiting for them to assess their priorities. Still, no rest for Warner – I’m digging further into the proposal and meeting the Renewals team leader tomorrow to see what “their plan” is. It may be that they’re either tackling it from another aspect (floatel) and we can tie in together for the business case. From a Plans point of view, all they really want from me is the broad brush of how much it will cost to install and operate. Wait out…

Magnus boom rests.

This is one of Ish’s I’ll be running with whilst he’s on Phase Four, and as far as I can see, currently consists of looking at big bits of steel meccanno which are being fabricated at a nearby workshop. Once complete they will be stuck on to some raised bolts on the platform’s floor and allow the cranes’ booms to rest upon them. Difficulties will involve ensuring they are manufactured to a tolerance of 5mm, and then lifting these 30-40m hunks of steel into place and bolting/welding them together. At some point in the next month I expect to have a formal handover of this project.

More work please

I’ve asked for more and will hopefully be getting some pipelines to work on. These are very good from an engineering side of things, and also (so John tells me) need to get done soon, which means I may get to see some of my work through to completion! We are looking at installation of these in November, so will be a fast turnaround.

Week 10 – Island Hopping (Scottish style)

Whist the South was suffering rain over the Jubilee Week, Liz and I took to the Inner Hebrides and had a week of uninterrupted sunshine! Did some good scrambling and walking, the occasional sea swim (not long til the big race) and then finished the holidays with the Lowe Alpine Mountain Marathon. I got back to work bronzed and rejuvenated (Liz got back to work shattered…)

Exploiting civvies…

If there’s one thing civvies do that the military don’t, its sponsor you! Maybe it’s because we’re all earning less money than they are, or maybe also because we find others’ challenges less impressive as we are all legends anyway, I don’t know, but the support I’ve had for my latest challenge (2.4 mile swim in a sea loch followed by a 125 mile cycle and culminating in a mountain marathon) is huge – complete strangers donating £50 and sending me e-mails of support! Check out the donations here: www.justgiving.com/chriswarner

Thai cages

Hey all,

Craziness here too as my boss is away in Brisbane a lot and I’ve been the go-to about reinforcement and shipping coordinateion….usually ending in me reading the code and then finding an excuse to visit the designers next door with brains much larger than mine!. I’ve recently received the reinforcing cages which are being prefabricated in Thailand and they’re being installed on site. I’ve posted heaps of photos to show the operation which should ‘paint several thousand words’….see www.roselliott.wordpress.com!

Weeks 12,13 & 14 – Being the subcontractor is not fun anymore

First, I must apologise for not blogging of late. Work has turned into 16 hour days, 6 days a week and time has been a rare commodity. This has been caused primarily by the pile of s*!t that I have taken on having now fully moved across to the MOF project. To summarise this, an average engineer has 1 or 2 work packs/lots that they are solely responsible for. Over the last 4 weeks I have managed to pick up 7, yes 7 of the things, all of which are either unplanned, in disarray or have severe contractual issues. I am not complaining about this as i have gone from zero to hero and am one of the “go to” engineers on site if you need something doing. Also, I’ve started to enjoy it a bit more although listening to the wrath of the construction manager is getting a little tiresome every day as he attacks me about something that has happened before me taking over the reins. Out of public view though he often has a quiet chat expressing his gratitude for my efforts and that he knows how bad a situation I’ve been dropped into. Winning his trust has been a quick win and despite his dislike for me slowing things down to get it right first time, he acknowledges that I am the only engineer able to produce anything that doesn’t require a NCR (non-conformance report) produced after completion!

Week 12 was a classic week on the GLNG MOF; set unrealistic targets, fail to meet them and then look like idiots in front of the client. We (JHG) failed yet again to get our own house in order for the majority of our works with only 1 element of the works programme actually achieved which was the Bulk Aggregate Berth (BAB) approach slab. This is a 13x10m RC slab ranging from 400mm deep to 500mm to create a natural run-off. At the start of the week the civils crew were also asked to place 8 pile cages complete with tie bar joints installed. This was never going to happen as Bechtel would not sign off the cages due to the fact that a) they weren’t as per the submitted design, b) they had been welded without JHG having a weld procedure in place (12 months into a project!), c) the welds completed were not certified nor undertaken with a crayon or any other sort of quality control mechanism! The plot thickens even further into weeks 13 and 14.

My main other focus points were to complete the admin and direct on the electrical works and installation of a light pole footing, attempt to track down the status of procurement for all of my work lots and manage an issues tracker for the project. There are some serious issues!

Week 13 was a short week as at 1430 on Wednesday started a 5 day R&R break. However….on the Tuesday afternoon the construction manager called a snap meeting with the engineers and had decided that because we were so behind in our work and failing to meet any targets that our R&R had been cancelled. Brilliant I thought to myself and as he finished his speech, justifying what he’d decided upon, the floor was opened to discussion. After the awkward silence that followed I thought I’d take the lead and asked outright whether JHG were willing to refund my non-refundable accommodation costs, rugby tickets et al i had booked for the R&R. Following his silence he said he’d need to speak to the PM but I knew that they wouldn’t. Strangely enough I was told an hour later that i wouldn’t have to come in over the R&R! Whilst the opportunity was there I also got in my excuses for the rest of the R&R blocks as we’ve got plans for all of them…I think he was actually pleased to hear that one of us could actually plan!

The Wednesday was a cracking day though for not being able to pour a simple light pole footing. For the last few weeks there had been deliberation about the depth and placement of the mast anchor bolts but the mast designers were content. Ironically, only an hour before we were due to pour, the designers emailed to say that they were no longer happy and that we had to increase the embedment depth! Pour cancelled, desperate scrabble to find longer threaded bar or couplers only to realise that it was never going to happen. Even during the R&R this continued (some were working) only for the client to turn round and refuse to accept the pour as the couplers that had been procured were not galvanized and only 4.6 as oppose to the bar at 8.8 grade steel. How i chuckled to myself from a distance but this exactly what happens all of the time…rush, rush, rush to get the job done but not get the detail right. As I keep saying to my supervisor “if this was the army, men would die due to these decisions!”

So I took my R&R, although I came back very tired, and enjoyed the metropolis of Brisbane, saw the Welsh lose to the Wallabies and bagged a couple of dives to test my new kit.

Week 14 was mostly about damage limitation with the light pole debacle and issues with the pile cages. By the end of the week i was glad it was over for 2 reasons. First, only 1 of the 4 planned concrete pours happened due to the usual lack of attention to detail and secondly the hangover from the build up to the previous R&R was still hanging around like a bad smell. So why only one pour? Easy…the management team had not sent a design change to Bechtel 12 months ago when it happened and just as we were about to pour they called a halt to the proceedings. Net result is that we now need to wait for the design change to be approved by the Bechtel design team in Houston, Texas which typically takes 2 weeks. That explains 2 of the pours which were for the piles and tie bar joints. I was very frustrated by this.

The 4th pour was halted due to more “on the bus, off the bus” decision-making over the light pole mast anchor bolts. Hindsight is great as it turns out that my predecessor had been doing dodgy “verbal” deals with the Bechtel engineers about the attached distribution board slabs, failed to red-line any drawings for submission and had we proceeded would have been in a world of pain as elements had been omitted that weren’t actually authorised to. Key learning point for Serevena the engineer, trust no-one, check everything 3 times and make sure that all of these “dodgy deals” are in black and white before proceeding.

So the above covers the main bits out of 2 of my work lots. The other 5 are potentially equally as well flawed so stay posted. The client wishes they never hired us (JHG), the JHG engineers all want to leave and the project has just announce a delayed completion date to the tune of 44 days, from August to mid-October. If this project is finished before I leave in early December I would be very surprised and may need to eat humble pie.

There are some positives though. I’m getting loads of good commercial experience, problem solving and covering most of the DOs fairly well. I actually enjoy the challenge of it all but most importantly is that the civils crew (my mob) are now the go-to team on the project which generally means I get the engineer lead, giving me the opportunity to shine. The senior project engineer has told me he’d employ me in a heart beat which was nice although I did have to remind him of my day job and it’s contract!

Apart from work, Team Serevena are all well. Baby Harrison is now 7 weeks old and we almost have a UK birth certificate for him which means we can apply for a passport, visa, etc. Austyn has moved up to level 2 in swimming lessons and can do doggy paddle (well), front crawl (badly), breast stroke (almost) and back stroke (lazily). Elliot talks complete gibberish as he tries to make sentences and is currently trying to master Tyrannosaurus rex but comes out with dinosaurus rex! Lisa is coping, looking after 4 boys (I include myself in that) is taking its toll but she’s heroically fighting through. Finally, Blaze is back on her feet at my parents following the trials and tribulations of losing Jackson and her whelping and is going for a week-long camping holiday to Scotland. Lucky girl!

That’s all folks.

Assumptions are the mother of all…..’£120k regains’?

Assumptions are the mother of all…..’£120k regains’?

Drilling & TaM Grouting

Bachy Soletranche (owned by Vinci) have a NEC3 Option A – Fixed Price (Activity Schedule) of £1.2m, to Drill & Tube a Manchette (TaM) Grout. The Activity Schedule was based on drilling, inserting TaMs, and grouting 384 fans of 4 holes (1,536 holes, each of 4 – 5m lengths) at 1.2m intervals along 230m of brick lined twin and single tunnel.

The objective of the permeation grouting was: “To mitigate the risk of high volume water ingress from groundwater sources derived from the upper aquifer and trapped aquifers in the Lambeth group strata into the tunnel works, especially in the form of scour or ‘piping’ of the made ground that remains surrounding the tunnels from their original construction.”

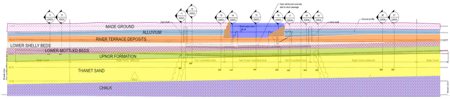

The design was intended to reduce the mass permeability of the made ground and any buried temporary work structures to that of a fine sand (1×10-7). The design ground parameters and geological strata were estimated using a series of boreholes along and adjacent to the tunnel. This information, combined with historical data about the original tunnel construction (believed to be ‘Cut and Cover’) was interpolated and transposed onto the existing tunnel structure to produce design sections along the length of the tunnel.

Design geological cross section of tunnel derived from borehole data.

Design geological cross section of tunnel derived from borehole data.

Design location of grout holes in relation to assumed geological strata in West (referred to by Bachy as North) Single Tunnel.

Design location of grout holes in relation to assumed geological strata in West (referred to by Bachy as North) Single Tunnel.

The Drilling & Grouting design was ‘accepted’ by the Client on the proviso, that grouting did not start until a trial was carried out to measure the pressure exerted on the existing tunnel structure as a result of grout injection. This parameters and methodology for this trial have been agreed and it is due to take place next week. Bachy were, however given permission to start drilling and are now 4 weeks into their programme. The Contracts Manager predicted 26 holes (13 per rig) per day and a 10 week programme. A series of problems (mechanical faults with rigs, poorly manufactured drill casings (manufactured specifically to fit in the Twin Tunnels), and high water pressures), meant that an average of 4 holes per day have been drilled, taking the programme to 16 weeks.

The use of a Stuffing Box to control high water pressures encountered during drilling operations.

The use of a Stuffing Box to control high water pressures encountered during drilling operations.

The consequences of this delay have a significant impact of subsequent works (replacement of the concrete invert slab and Twin Tunnel replacement by construction of a cofferdam). The financial impact for Bachy has the potential to be disastrous, reflected in the change in attitude of the Contracts Manager to recoup every penny available by scouring the ‘attendances’ on the contract and submitting Early Warning Notices (EWN) for any potential cause of delay. This has sparked yet more tension with the Vinci Works Manager and Works Supervisors, who feel they are ‘baby sitting’ the sub-contractors.

There is a 10% cap on delayed damages, which at this initial rate of progress, would equates to £120k of costs and ultimately lost profit for Bachy. However, once the cap is reached, arguably Bachy have no financial incentive to continue working extended hours and weekends to complete the job (a measure introduced in an attempt to regain lost time).

Drilling rig drilling (left), grouting tube from silos at surface down ventilation shaft to grouting plant (back centre) and making up TaMs for insertion into the holes (right).

Drilling rig drilling (left), grouting tube from silos at surface down ventilation shaft to grouting plant (back centre) and making up TaMs for insertion into the holes (right).

Grout silos and agitator tank on central compound from where grout lines are run down ventilation shaft into the tunnel.

Grout silos and agitator tank on central compound from where grout lines are run down ventilation shaft into the tunnel.

Fortunately for both Bachy and Vinci (who are also liable for delay damages to Crossrail), it has transpired that the geological assumptions were not wholly reflective of the in-situ conditions. All the holes drilled in the West Single and Twin Tunnel showed there to be varying degrees of Made Ground between the tunnel structure and the natural ground (all of which was clay derived), and also proved that at the level of drilling, the adjacent strata was Lambeth Group, and not as anticipated, River Terrace Deposits.

The high volume and pressure of water in the initial holes, as well as the high uptake of sleeve grout intended to fill the void between the TaM and the hole, suggests whilst there is no permeable Made Ground, there is a ‘Contact Zone’ (a void usually filled with water) between the tunnel structure and the natural ground. The question now sat with the Geological Consultants is how the tunnel was actually constructed (temporary propping in the clay layers with cut and cover above, backfilled with excavated clay?), and most importantly what assumptions must be redefined in anticipation of the Twin Tunnel replacement.

A series of Bachy, Vinci and Crossrail design meetings have now agreed to Bachy’s proposal that grout holes along the section already drilled must extend 0.5m into the natural ground, thus shortening the design length (which accounted for Made Ground) by up to 2m. Concurrently, a trial of Contact Grouting (i.e. without TaMs) using just the top and bottom grout hole, will be carried out on the opposite wall. Already, the reduction in grout hole lengths has increased Bachy’s production rate by 200%, and providing the Contact Grouting trial is successful, the significant reduction in anticipated scope could potentially be the difference between breaking even or making a substantial loss.

What does the contract say?

From a project perspective, encountering clay at a higher level than anticipated is certainly good news, particularly for the Twin Tunnel replacemnet. From a contractual perspective however, Bachy based their design on geological assumptions. These assumptions have now changed, and so therefore must their design and methodology. The change in methodology, once agreed may have implications on their payment. Currently, monthly payments are made in accordance with an Activity Schedule (e.g. holes drilled – per meter length). This is set to reduce by over 50% and therefore, the current system of payment would never allow Bachy to claim for the total tendered amount. Clearly, Bachy have every intention of claiming their full Fixed Price payment (albeit less delay damages), equally Vinci will be looking offset their delay damages against the reduction in scope. As the Section Engineer responsible for the works, and more often than not the ‘buffer’ between the 2 parties, I think I may have the ‘Eastenders’ of a TMR 2 on Contractual Relationships…?!

Corrupting the minds of future generations…

Careers Day – Dumbarton Middle School

USACE has a huge outreach programme which covers targetted media, public information and also encompasses the promotion of science and engineering through career days at local schools. I went along and convinced them all to come and join the British Army. Having listened to other speakers at the bureau, I have decided that I want to be a museum curator or a fireman when I grow up. The good thing about all of this is that it help hit some of the development objectives for ICE and also opens up a bunch of extra curricular activities.

EDC SolarWall®

The recent requirement for changes to the design has resulted in a request for an extension from the contractor (time only) which will be honored. This will result in a delay in the submittal of the 65% design solution and potentially a delay on the expected completion date.

We are also negotiating on means of providing the monitoring process. Everyone knew we would need sensors and monitors, but the installation of wi-fi or cabling and power for the sensors appears to have been previously overlooked. Not to worry – it’s all at the contractor’s risk, but any proposal needs to be incorporated to the infrastructure of the building accordingly.

As a result of recent design changes the contractor is seeking to use an epoxy coat for steel columns, but the customer is not keen and keeps sending sketches of what they think it should look like to the contractor. This opens up a world of pain, because if this is interpreted as authority to provide a final solution, then we may be promising mods and changes that aren’t approved or financially appropriated……and folk have gone to proison over here for stuff like that. The contractor needs to take the idea, make it his own and then propose it back to us so we can say ‘hey what a good idea – let’s make the mod…’

DDSP Buildings 732 / 760

My comments on the PMPs have clearly ruffled feathers. Every job by USACE ‘must’ have a PMP and people just look at this as a hoop to jump through. Therefore the PMPs tend to be very generic and lack any kind of insightful risk analysis or mitigation thereof. I have been asked to educate the folk that prepared them and they are not being overly receptive.

Ashley Reservist Center

The awarding District has decided that they do not want the approved testing lab (hired by the contractor) to do the petrographic testing of the defective concrete previously identified. The fear is that the lab is ‘on side’ with the contractor. I don’t know if this creates any contractual issues (can we actually tell them what lab to use – or is it their business?) I pointed out that the lab is on the approved list because USACE has inspected them and authorised them. To not use them is to question the ability of our own departments. Also – it is more than it is worth for the lab to get itself struck off the list as we provide a hige amount of work for them. I also feel that by forcing them to change the lab, we are openly saying to them that we do not trust any of their previous results which will not do much for the ‘partnership’.

The office manager here is contemplating paying for the tests from our own office budget to try and avoid some of these issues – in which case I recommended that they also test some cores that were taken from the foundations to pass services through. If these are found to be lacking then it confirms that the testing regieme has been flawed from the beginning……but would also prove that the whole building is sitting on sub-standard foundations….and that will get juicy.

Other News

Not simply content with just shooting and stabbing each other – the US is now having issues with ‘face eating’. Sorry…I correct myself ‘naked face eating’ whereby a naked man in miami eats his victim’s faces. Far from just being abhored, it’s almost becoming a tourist attraction. The Miami tourist board has updated it’s advertising accrodingly.

For Sale

Pallet of smoke and mirrors (unused). Surplus to requiremnet following CI visit.

2 Months In

Hi everyone. This is a shamelessly AER focused post so please feel free to lambast me for my dryness. Lambast me baby! More interesting (picture based) posts to follow shortly…

Here are just a few of my general experiences and observations from the first 2 months on site. I’ll do more on the technical nitty-gritty of the tasks over the next few weeks.

Experience: Updated Roles and Responsibilities

So, I’ve picked up a few extra responsibilities over the last few weeks; I’m now Services coordinator for all Public and Public/Private Shared facilities, Site Supervisor for two discrete projects, and the Services Defects Manager for all areas of the Programme already completed but still within their defects liability period. Sir John is certainly getting his dollars’ worth out of DDK.

On the public/shared side of the site, that means I’m overseeing the coordination of services in a surgical day procedures unit, a theatre recovery ward, a catheter laboratory (more on which later), a new kitchen, a medical records and training facility, a supplementary services (chapel, AV etc.) unit, a central energy building, and a heat distribution plant room. All of these involve refurbishment or expansion, and so working around other live services and, mostly, in areas where patients are still being treated.

Observation: The moto in all of this is very much hospital first and, as the hospital seems to have a pretty much zero tolerance approach to any disruption what so ever, this means anything that affects a hospital service or operation, generally occurs at midnight or on a Sunday, or (and this is my favourite) both.

Analysis: It might seem that the programme planners were rather short sited in developing this strategy; the CI remarked that it would probably have been a lot cheaper to simply build a new hospital next door and then knock down the old one. It is certainly true that the cost of the constant frustration of progress, because of the need to work out of hours, is significant; the hourly labour rates, probably the most expensive element of any work packet I’ve been involved in so far, doubles as soon as 4pm passes.

The reason is threefold:

1. There is no space. The city of Joondalup, and the suburbs around it, are expanding so fast (in no small part driven by the influx of Irish, Spanish, Italian, and British workers fleeing the hopeless prospects in Euroupe, lending Joondalup its nickname of ‘Pom City’) that there is simply no space to build a new hospital other than inside the old one.

2. Australia does not have publicly funded hospitals in the same way the UK does. Many facilities in the existing hospital are privately owned and funded. No one would pay to replace or relocate them, when they are perfectly profitable where they are.

3. Each ward or facility is in fact a business in its own right. When the refurbishment of one affects the operation of another, there may be significant compensation claims. As such the hospital’s operator, Ramsey Health Care, is particularly unwilling to sanction any interference with business as usual, unless it absolutely can’t be avoided. With each patient paying, on average, $1000 a day, not to mention the everyday exigencies of any hospital, the choice between closing beds and making builders work overnight is a simple one.

The bottom line is that it’s too difficult, and too expensive (to individual business units) to do anything other than refurbish and expand the hospital from the inside out.

Experience: I’m also the site supervisor, normally a role given to a bricks and sticks man, for the Central Energy Building and the Heating Plant Room. This means that in addition to coordinating the services, I’m also supervising and coordinating all of the civil (not that much) and general building works.

Whilst the civil and building things I’m involved in aren’t particularly technical – we have consultants for that – they come in tremendous volume, and I’m having to learn about slab, column & beam construction, sub base properties, and general building techniques and practice. The civil training we E&Ms get at the RSME is very useful here, but more knowledge of the difference between an PFC and a Z Purlin, for example, would be useful to us.

Analysis: Perhaps the steepest part of my learning curve has been to do with simply understanding what it is that the consultants and contractors are talking about. Whether talking about an purlin, a reveal, or a bulkhead, there is a good deal of terminology, that any engineer, regardless of discipline, needs to be conversant with.

Recommendation: I have found that 2 books have been invaluable as desk guides. First is the Building Services Pocket Book, published by Newnes. This is a very good practical guide to services in any building; focusing on mechanical services – which I now know dictate the design of all high level services layouts – it offers invaluable notes and is simple to understand in a hurry. The second is the Architect’s Handbook, published by the Architectural Press, which is an excellent general guide to building. I’ve also see the Building Construction Hand Book, published by Butterworth-Heinemann, but this is a little basic compared to the other two. I would recommend that all students on PET be issued with the first two books, or something similar. Alternative suggestions anyone?

Experience: Finally, as the Services Defects Manager, I’m responsible for receiving, understanding, and assigning the Client’s defects notifications, as well as identifying many of them myself. I rather walked into this job, as I found so many defect as I walked around the place, that it became easier to deal with them myself than to staff them to someone else.

Analysis: Essential to doing this properly is the ability to compare what is in from of you with the drawings. I have found that it has taken me a few months to understand, quickly, the myriad of technical drawings that are encountered on a construction site. Because the difference between a quick and amicable solution and a protracted and increasingly entrenched e-mail rally often lies in understanding the drawings and specification the fastest, the ability to rapidly interpret technical drawings would enhance the preparedness of PET students for Phase 2 work.

Recommendation: More technical drawing comprehension should be incorporated into phase 1; everything from the EWIS to the structural steel. I have plenty of PDF example drawing that could be used to set such exercises and can send them if required.

And Finally: In an effort to prevent this from being the driest post since, well ever, here are some pictures of the weather in Perth over the last few days – get it? ‘Dry’? Yack yack!

And worse is forcast for tomorrow – last week it was 30 and sunny?!?

Quantity vs Quality

Quantity vs Quality

3 months into my placement, I have learnt a number of lessons. However, the most prolific, which seems to define the difference between success and failure, is that quantity (or at least payment thereof) is irrelevant without quality. Whilst this should evoke confidence that the final product is ‘defect free’, rigid insistence that the final product is 100% compliant with the original specification, can cause costly and at times unnecessary delays. A couple of examples are as follows:

Re-profiling

Re-profiling works are almost complete….well, according to the Contractor?! With only 60m left to go, Vinci are understandably looking to the Client to sign the Substantial Completion Certificate in order to receive payment for the works. The key problem is agreeing the methodology for checking levels, agreeing what substantial completion actually means and trying to interject a level of common sense into the process. Approximately 80% of the re-profiled area is within the -45mm tolerance, inevitably however, there are a few spots which are outside this tolerance. It has been deemed that a laser level will be most suitable for checking the entire 6.6km2 area, by dividing the slab into sections of even gradient. The Client is proposing that all points outside the tolerance be raised in a Non-Conformance Report, and a Substantial Completion Certificate will not be issued until the works are 100% compliant with the original Project Managers Instruction (PMI) (i.e. lowered or ‘raised’ to be within tolerance). The Vinci stance, (well at least at Section Engineer level) is that the slab will be covered by a minimum of 80mm of blinding before the final rail slab is placed, therefore what is driving this degree of accuracy? A decision is yet to be made but at £800 per day to hire the Rockwheel, Vinci are understandably keen to reach an agreement soon.

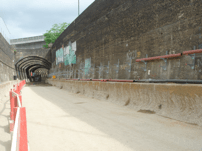

Western Approach Ramp re-profiled to SSL (note constant seepage).

Western Approach Ramp re-profiled to SSL (note constant seepage).

Eastern Approach Ramp re-profiled to SSL (note drying out of ramp following initial seepage).

Eastern Approach Ramp re-profiled to SSL (note drying out of ramp following initial seepage).

Piling

Piling is now progressing well and the Continuous Flight Auger Piles (CFA) and Controlled Modulus Columns (CMC) are finally complete on the West Surface Site, and have since moved to the East Surface Site. The piling works are considerably over budget and more than 8 weeks delayed. 6 changes of sub-contractor team would suggest there were some internal problems, however, a substantial percentage of delays were attributed to stringent Client quality control procedures. Whilst there is no arguing that the Client has every right to check contractor and sub-contractor works, a team based approach to problem solving, and a spirit of ‘mutual co-operation’ was often replaced with inflexible procedures and unpredictable responses at inspection points.

The last of the CMC piles on the West Surface Site, from the site boundary to the top of the Approach Ramp

The last of the CMC piles on the West Surface Site, from the site boundary to the top of the Approach Ramp

Whilst the examples given demonstrate how a degree of Client flexibility could facilitate the construction and handover process, the bottom line remains that the contractor proposes and agrees the Inspection & Test Plan (ITP) before works start. The difficulty I have experienced when writing ITPs, is knowing how much detail is required to effectively monitor work and control quality, without impacting too much on production (i.e. ‘quantity’). The key is including sufficient Witness Points, whilst ensuring that the parameters for Hold Points are fully understood, agreed, and can be met.

In my opinion, a consequence of convoluted Client ‘Acceptance’ procedures, is that not enough time and consideration (by both Client and Contractor) is dedicated to devising suitable ITPs. The focus is gaining Client ‘Acceptance’ by the quickest possible means in order to start production. Inevitably, the problem then comes at the first Hold Point, where ‘quantity’, if it is not of the agreed ‘quality’ rapidly becomes wasted effort.

The risk for a contractor or sub-contractor of not providing the predicted ‘quantity’ within an agreed time is mitigated by an elevated tender price, and the ‘unforeseeable/exceptional circumstances’ clause. However, the impact of not fully understanding, or being 100% compliant with the pre-agreed ITP can have far wider reaching consequences; and there are no clauses for damages!

An exception to the rule….

Dewatering The Chalk and Thannet dewatering wells were turned on 3 weeks ago and the ground water is now being pumped into the docks. Piezometer readings are being used to gauge progress, and a Chalk well pump was replaced with a smaller one, after results showed that the well was actively (as opposed to passively) drawing down the water level thus risking differential settlement in surrounding strata. In this example, the ‘quantity’ of water, is inextricably linked to the success of the works, and unlike the examples above, is ultimately a measure of the ‘quality’ of the scheme. Interestingly however, if the dewatering is unsuccessful the risk sits with the Vinci. The sub-contractor carries no responsibility, despite the dewatering scheme being their design. And presumably, if the proposed scheme is not effective (i.e. the ‘quantity’ of water draw down not achieved), the sub-contractor will revise it – for a price!